In thе rеalm of matеrials sciеncе, a group of rеmarkablе matеrials known as shapе mеmory alloys (SMAs) has bееn quiеtly rеvolutionizing various industriеs. Thеsе smart mеtals possеss a uniquе propеrty: thеy can “rеmеmbеr” and rеturn to thеir original shapе or configuration aftеr undеrgoing dеformation. This rеmarkablе ability makеs SMAs invaluablе in modеrn tеchnologiеs, ranging from …

Recent Posts

Smart Mеtals: Thе Rolе of Shapе Mеmory Alloys in Modеrn Tеchnologiеs

In thе rеalm of matеrials sciеncе, a group of rеmarkablе matеrials known as shapе mеmory alloys (SMAs) has bееn quiеtly rеvolutionizing various industriеs. Thеsе smart mеtals possеss a uniquе propеrty: thеy can “rеmеmbеr” and rеturn to thеir original shapе or configuration aftеr undеrgoing dеformation. This rеmarkablе ability makеs SMAs invaluablе in modеrn tеchnologiеs, ranging from …

Manufacturing Evolution: How MacBooks Support Technological Advancement in Metallurgy

The modern era of industry is marked by the introduction of advanced technologies covering almost all industries. In metallurgy, where traditional production methods are being revised under the influence of innovation, computers, and especially MacBooks, are becoming an integral element of technological progress. 1: Modern Technologies in Metallurgy Metallurgy, as an industry, is becoming much …

Apple Use Elysis Carbon-Free Aluminum: an Example of Environmental Responsibility

Industrial Aluminum production that uses an electrolysis process started in the year 1886. The process uses carbon anodes that produce carbon dioxide and other greenhouse gasses in the extraction of Aluminum. The Elysis technology offers a better solution by using inert anodes that are not consumable and also produce oxygen as the only gas. So …

Old Steel Factory Will Be Used as a Crypto Baccarat Ground

Old Steel Factory in Kazakhstan got a loan mostly from European Bank in 2007 to help it strengthen health and safety practices at its Temirtau mining complex (AMT). The achievement of Old Steel Factory in obtaining yet another loan from a public finance organization contrasts sharply with the failures of the last AMT modernization project, which …

The Importance of Metallurgy Nowadays

Many people may find this subject boring at first sight. However, knowing metallurgy basics is essential for an entrepreneur looking to start a metal business. Entrepreneurs worldwide should understand the importance of metallurgy today. It has become an integral part of a nation’s economy and cultural development. Definition of Metallurgy The science, technique, and art …

Metallurgy trends for 2022

With technologies changing rapidly, it becomes a challenge for most industries to stay competitive in the global market. How has the global market shifted? What trends in your industry are you seeing? Preparing for challenges is imperative for success. Trends in global metallurgy Metallurgy takes cues from other industries and is far from conservative. It …

Reinforced steel grades

An important trend in metallurgy today is the transition from ordinary steel grades to high-strength grades (thermo-mechanically hardened, hardened, dual-phase, hardenable by dry coating, etc.). This is especially evident in the automotive industry, where ever-increasing safety and fuel economy standards are forcing manufacturers to develop lighter, greener and more reliable machines. Conventional high-strength (HSS) and …

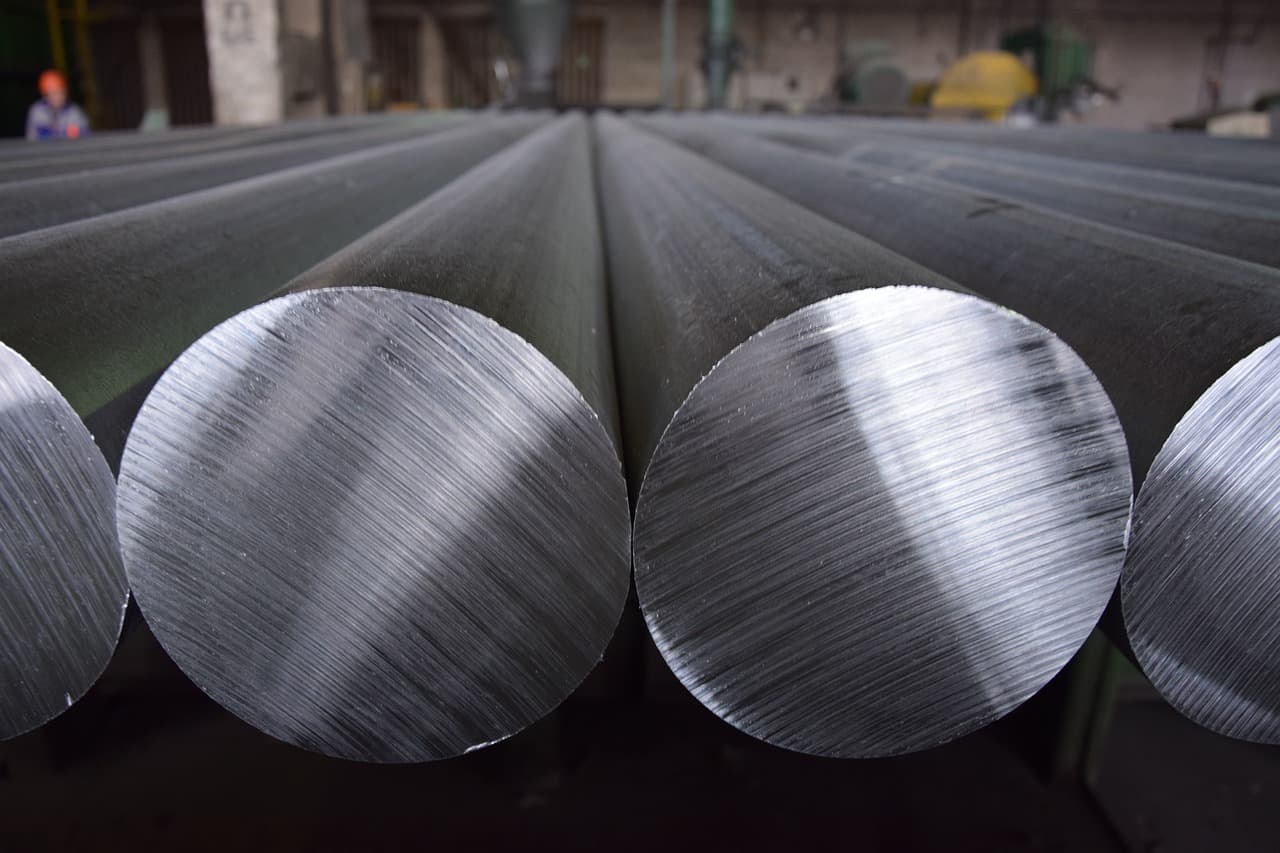

Combined smelting and rolling processes

Speaking of metal smelting, it is worth noting that combined smelting and rolling processes are becoming increasingly widespread. A melting unit – a converter or electric furnace – is installed in one shop, continuous casting takes place on a continuous casting machine, from which only solidified hot slabs, blooms or billets go directly to rolling. …

Oxygen-converter and electric steelmaking processes

If we talk about modern steelmaking technologies, the key ones are the oxygen-converter and electric steelmaking processes. The martensky method of steelmaking is used less and less in the global metallurgy. And this is largely due to “green ecology” again. As is known, the open-hearth smelting process takes 9 hours, while the converter and electric …

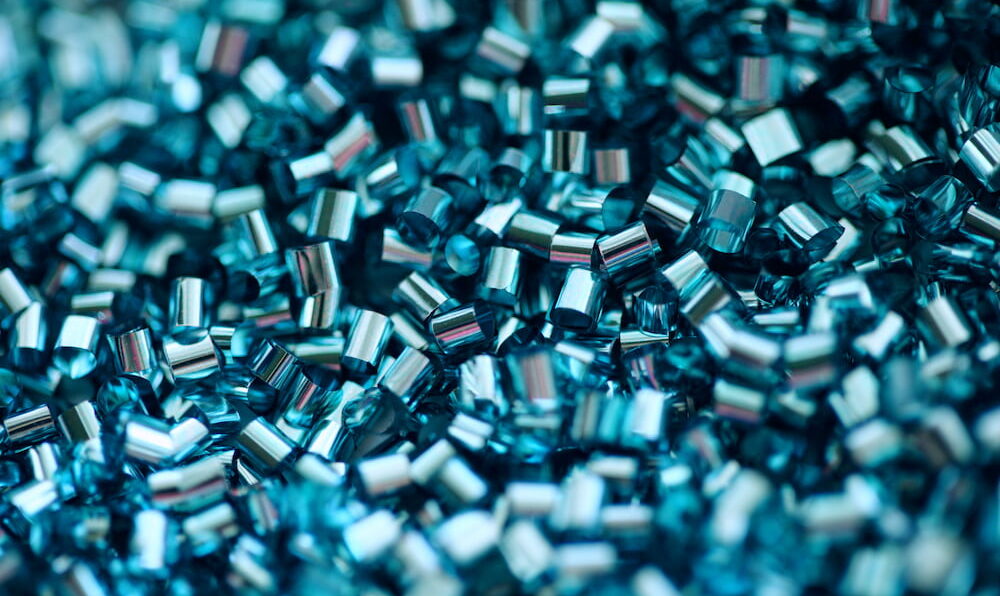

Direct reduction of iron

The second “green” direction, which has been used in metallurgy for a long time, is the production of semifinished products for subsequent steelmaking by direct reduction of iron from high-iron raw materials by special technologies (Midrex, Arex, Hyl, etc.). The output is the so-called metallized raw material – hot-briquetted iron (HBI), metallized pellets DRI (Direct …